Scald Tank Solutions for Safe and Efficient Heating

9 月 . 01, 2024 02:30 Back to list

Scald Tank Solutions for Safe and Efficient Heating

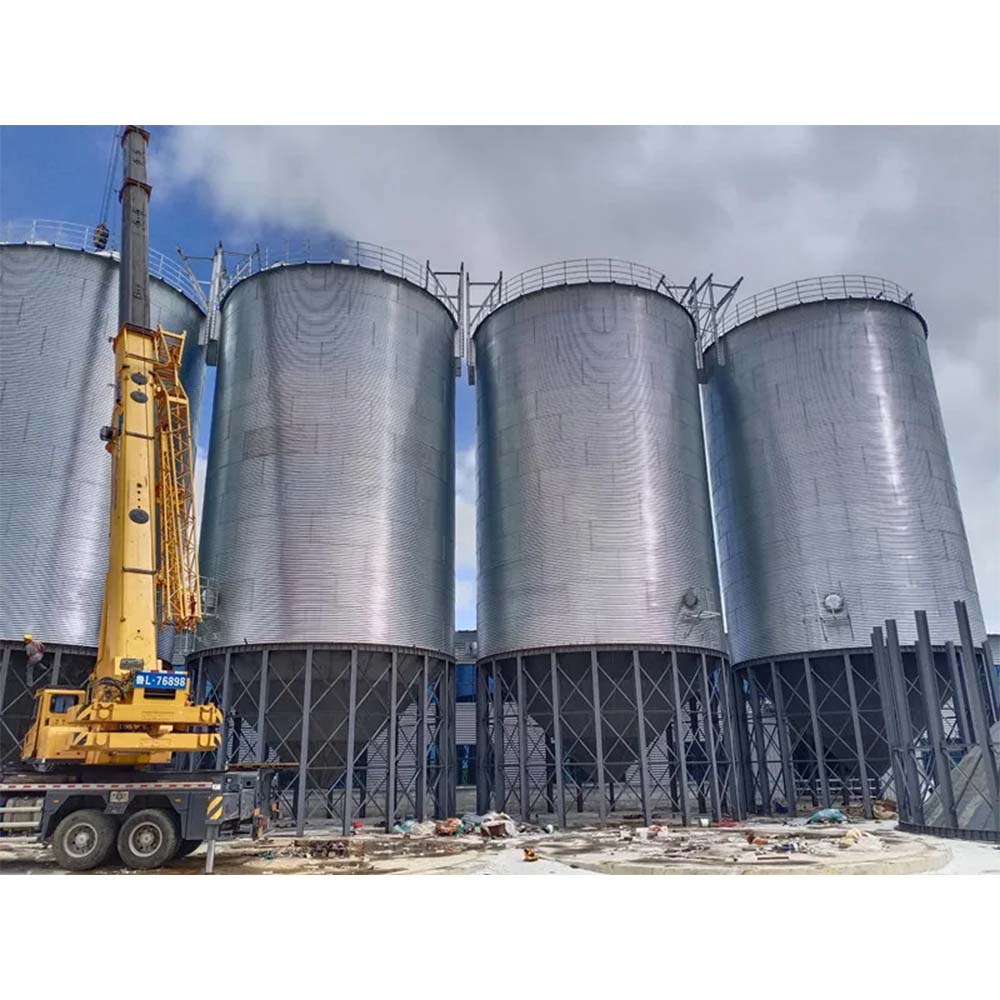

Understanding Scald Tanks Essential Equipment in Thermal Processing

In various industrial applications, particularly in food and beverage processing, the use of scald tanks is vital for ensuring product safety and quality. A scald tank is designed to immerse products in hot water or steam at controlled temperatures, a process known as scalding. This technique is crucial in several stages of production, from the initial treatment of fruits and vegetables to the processing of poultry and meat.

Scalding serves multiple purposes. Firstly, it effectively removes dirt, debris, and undesirable microorganisms from the surface of products. For instance, in fruit and vegetable processing, scalding helps to loosen skins, making them easier to peel, enhancing the quality of the final product. In meat processing, it can aid in feather removal in poultry processing. By subjecting the products to high temperatures for a short duration, manufacturers can achieve cleanliness without compromising texture or taste, making scald tanks an indispensable element in the production line.

The operation of a scald tank requires careful temperature and time management to maximize efficiency while maintaining safety standards

. Typically, water is heated to temperatures ranging from 60°C to 80°C (140°F to 176°F), depending on the type of product being processed. The immersion time is also crucial; it must be sufficient to achieve the desired effect but not so long that it negatively affects the product’s quality. Modern scald tanks come equipped with advanced technology to monitor and control these parameters, ensuring consistency and repeatability in the scalding process.scald tank

Moreover, the material selection for scald tanks is significant. Stainless steel is often preferred due to its resistance to corrosion and ability to withstand high temperatures. Additionally, tanks may come with features such as insulation to maintain heating efficiency and reduce energy consumption, making them more environmentally friendly.

In recent years, innovations in the design and operation of scald tanks have emerged. Automated systems can now integrate scald tanks into broader processing lines, allowing for real-time monitoring and data collection. This technological advancement helps in maintaining compliance with food safety regulations and improving overall operational efficiency.

In conclusion, scald tanks play a crucial role in the food and beverage industry, improving product quality and safety through effective thermal processing. As technology continues to evolve, the efficiency and effectiveness of scald tanks will likely improve, further enhancing their significance in modern food production. For manufacturers committed to quality, investing in advanced scald tanks can lead to significant benefits in both product integrity and operational efficiency.

-

Battery Layer Cage Systems With Automatic Feeding Machine

NewsMar.07,2025

-

Hot Selling Multi Function Vacuum Packaging Machine

NewsMar.07,2025

-

Chicken scalder plucker machine for sale poultry scalder chicken plucking machine

NewsMar.07,2025

-

Egg Tray Making Machine 1000, 2000, pulp molding machine

NewsMar.07,2025

-

Automatic Feeding Line System Pan Feeder Nipple Drinker

NewsMar.07,2025

-

cage layer chicken

NewsMar.07,2025