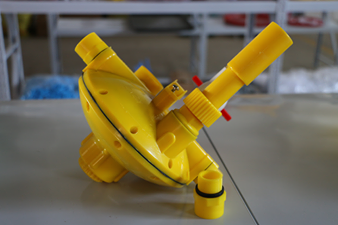

vacuum plastic packaging machine

2 月 . 14, 2025 22:41 Back to list

vacuum plastic packaging machine

In the rapidly advancing world of packaging technology, vacuum plastic packaging machines stand out as an innovation that significantly impacts product preservation and distribution efficiency. These machines have become an indispensable asset for industries ranging from food processing to electronics, helping businesses enhance product shelf life and ensure pristine condition upon delivery.

Authoritativeness in Quality Assurance Voices of authority within the packaging industry consistently emphasize the importance of quality assurance in vacuum packaging. Leading manufacturers adhere to stringent international standards, employing rigorous testing protocols to ensure machine reliability and durability. This dedication to quality translates into trust; businesses are confident in their investment, knowing that the machinery will deliver consistent performance over time. Expert organizations and industry associations frequently highlight the technical specifications and certification of vacuum packaging machines as crucial factors in choosing the right equipment. These endorsements serve as a guiding light for businesses, reinforcing that opting for high-quality machines is vital for maintaining compliance and securing product safety. Trustworthiness Through Innovation Trust in vacuum plastic packaging machines is deeply rooted in continuous innovation. As consumer demand evolves, so too do the machines, with manufacturers integrating cutting-edge technology like IoT connectivity and real-time monitoring. These advancements enable businesses to track packaging processes remotely, ensuring high levels of efficiency and accuracy. Moreover, reputable manufacturers offer comprehensive after-sales support, including training, maintenance, and readily available spare parts. This commitment to service excellence builds trust among users and ensures long-term satisfaction with the products. Conclusion The role of vacuum plastic packaging machines in modern industry is undeniably influential. They offer a sophisticated solution to age-old challenges of product preservation and safety. Companies investing in these technologies gain not only improved operational efficiency and prolonged product lifespans but also a fortified reputation for quality and reliability. By focusing on enhancing expertise, maintaining authoritative standards, and nurturing trust through innovation, vacuum packaging machines are paving the way for the future of industrial packaging.

Authoritativeness in Quality Assurance Voices of authority within the packaging industry consistently emphasize the importance of quality assurance in vacuum packaging. Leading manufacturers adhere to stringent international standards, employing rigorous testing protocols to ensure machine reliability and durability. This dedication to quality translates into trust; businesses are confident in their investment, knowing that the machinery will deliver consistent performance over time. Expert organizations and industry associations frequently highlight the technical specifications and certification of vacuum packaging machines as crucial factors in choosing the right equipment. These endorsements serve as a guiding light for businesses, reinforcing that opting for high-quality machines is vital for maintaining compliance and securing product safety. Trustworthiness Through Innovation Trust in vacuum plastic packaging machines is deeply rooted in continuous innovation. As consumer demand evolves, so too do the machines, with manufacturers integrating cutting-edge technology like IoT connectivity and real-time monitoring. These advancements enable businesses to track packaging processes remotely, ensuring high levels of efficiency and accuracy. Moreover, reputable manufacturers offer comprehensive after-sales support, including training, maintenance, and readily available spare parts. This commitment to service excellence builds trust among users and ensures long-term satisfaction with the products. Conclusion The role of vacuum plastic packaging machines in modern industry is undeniably influential. They offer a sophisticated solution to age-old challenges of product preservation and safety. Companies investing in these technologies gain not only improved operational efficiency and prolonged product lifespans but also a fortified reputation for quality and reliability. By focusing on enhancing expertise, maintaining authoritative standards, and nurturing trust through innovation, vacuum packaging machines are paving the way for the future of industrial packaging.

Latest news

-

Battery Layer Cage Systems With Automatic Feeding Machine

NewsMar.07,2025

-

Hot Selling Multi Function Vacuum Packaging Machine

NewsMar.07,2025

-

Chicken scalder plucker machine for sale poultry scalder chicken plucking machine

NewsMar.07,2025

-

Egg Tray Making Machine 1000, 2000, pulp molding machine

NewsMar.07,2025

-

Automatic Feeding Line System Pan Feeder Nipple Drinker

NewsMar.07,2025

-

cage layer chicken

NewsMar.07,2025